SS Energy Efficient Single Entry Condenser

M/s Prompt Spray Engineers the Multijet effect and the pans in the Sugar factory operate under vacuum. The suitable equipment to produce this vacuum is therefore required. The condenser is device for the ex- change of heat between vapour and cold water.

The exchange will be more complete as contact between two fluids is more inti- mate. Thus the result will depend on surface offered by water and its contact time. Our condensers provide required 26 Inches vacuum within half to tow minute.

After keeping in view the basic principles Prompt Spray Engineers has designed SS Energy Efficient Condensers with thermo plastic (Engineering Plastic) nozzles which are well resistant to acidic actions and high temperature. The condensers are manufactured out of corrosion-resistant materials like SS 304.

The staggered arrangement of Jet and Spray Nozzles facilitates water dispersion for condensation and ejection of noncondensable gases thorough well-designed venturi.

The adequate size well-designed manhole for jet box and condenser shell, which can be easily operated manually is provided to facilitate easy & fast maintenance. Our condensers are designed for required vapor load with optimum cross- Sec- tional area for vapor condensation and ejection of non condensable gases.

Condenser Jet & Spray nozzles are designed for low head pumps and manufac- tured in thermo plastic (Engineering Plastic) and are provided with leak proof rubber joints to avoid pressure losses and increase efficiency. Separate special type (V type) strainer of adequate length is provided to the Jet box for preventing chocking of nozzles.

Cleaning mechanism Valve is provided inside the shell of the condenser to facilate cleaning of strainer in few seconds without breaking the vacuum. Our SS Pen condensers require less power as compared to traditional condens- ers. Condensers work at less inlet pressure of water to the range of about 1.2 to 1.3 kg/cm2.

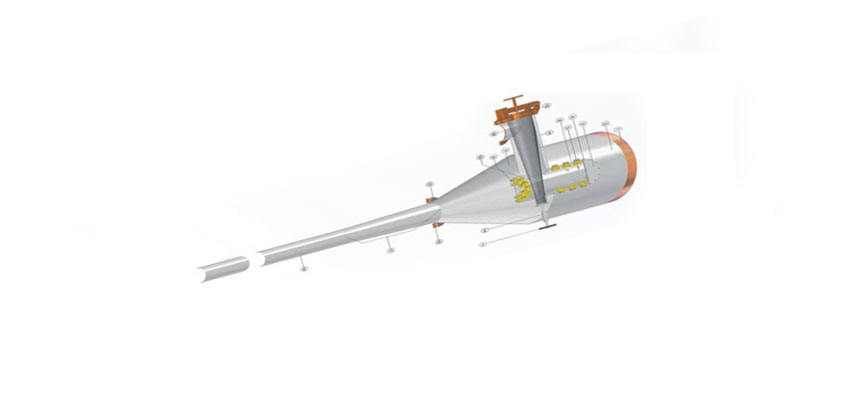

Part List of Ss Energy Efficient Single Entry Condenser

- MS Flat for matching to the Vapour Pipe.

- SS 304 Condenser Shell.

- SS 304 Jetbox Top Flange.

- SS 304 Nut with Bolt.

- Thermoplastic automized Spray Nozzles.

- SS 304 Jet Box.

- SS 304 Condenser bottom cone.

- Condenser Manhole (not shown due to image limitation)

- Thermoplastic Jet Nozzles.

- SS 304 Staineer.

- SS 304 Staineer Shell.

- Staineer Manhole.

- Condenser Bottom cone Flange.

- Staineer cleaning maykyanizem.

- Staineer Cleaning Valve Wheal.

- Venturi Flange.

- SS 304 Venturi.

- SS 304 Tailpipe.

- SS 304 water Inlet Nipple.

- SS 304 Jet Box Jet Plate